SWISS CNC SCREW MACHINING

About Our Swiss Screw Machining Process

A Swiss CNC Screw Machine feeds the stock through a guide bushing. This means the OD turning tool can always cut the stock near the bushing, and therefore near the point of support, no matter how long the workpiece. DW Products is utilizing twin spindle (main & sub spindle), live tooling, Y-axis, C-axis and 12-foot automatic bar loaders in 12MM, 20 MM and 32 MM bar stock diameters in round, hex or square bar shapes, which make our Swiss CNC’s run uninhibited.

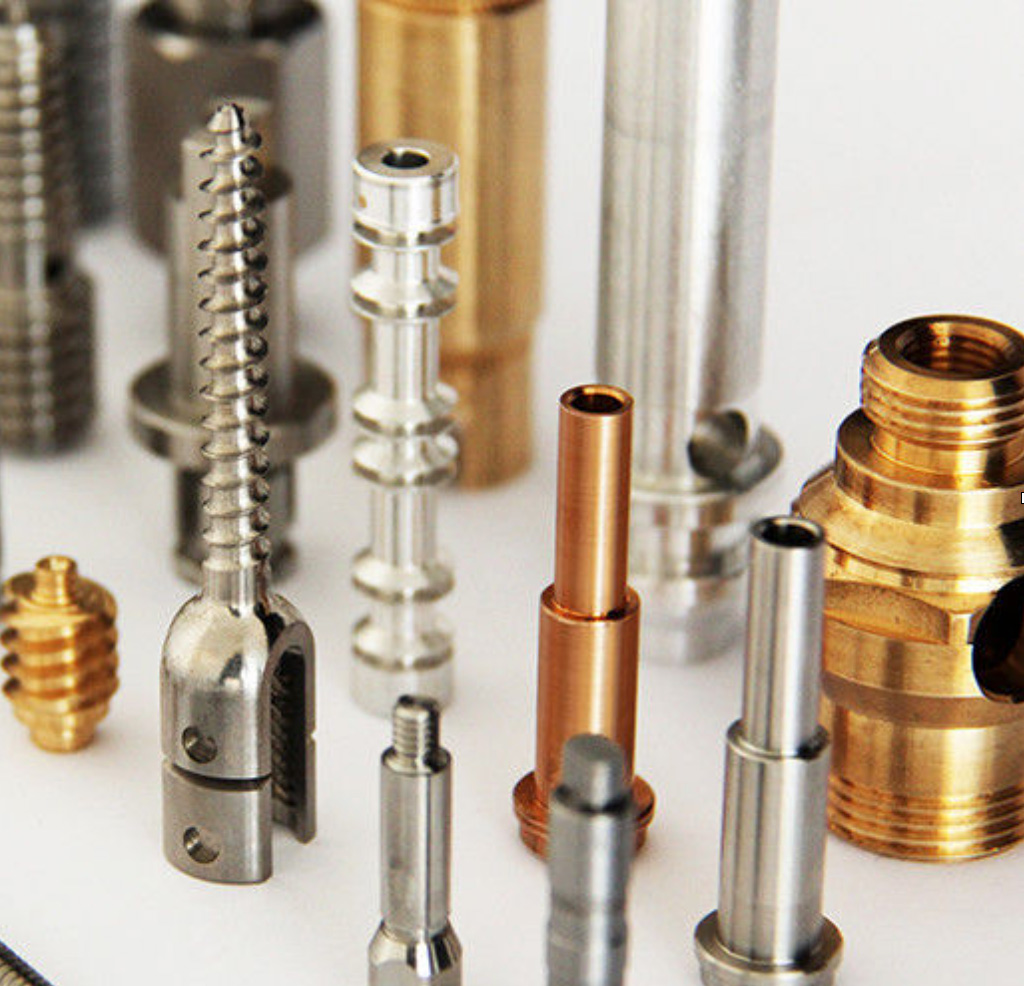

DW Product’s Swiss CNC screw machines have the capability to do all the typical machining operations in one set-up. These operations include but are not limited to turning, knurling, thread rolling or cutting, drilling, boring, reaming, burnishing, eccentric diameters and drill locations, cross holes, gun drilling, slotting, milling or rotary broaching. DW Product’s Swiss Screw Machines can drop a complete part that saves you money.

Swiss Screw Machining Applications and Services

Swiss screw machining is different from other machining capabilities and processes because it uses guide bushings to minimize the distance between the cutting tool and main spindle. This design difference results in reduced workpiece bending and less deflection at the cutting surface.

Manufacturers use CNC Swiss screw machining to produce a broad range of standard and custom cylindrical components, like shafts, screws and various fitting types. The precision and accuracy make the process ideal for producing high-performance precision parts for industries with strict quality standards.

Some of the most common industries Swiss CNC screw machines serve include:

- Agriculture.

- Automotive.

- Construction.

- Electronics.

- Hydraulics.

- Heavy vehicles.

- Medical devices.

- Power generation applications.

- Recreational vehicles.

CNC Swiss Screw Machining Benefits

Among the primary advantages of using CNC Swiss screw machines are their efficiency and speed. Swiss Screw Machining outclasses other lathe designs by using tools on multiple axes, allowing extra functionality for turning and milling while offering a single turnkey machining solution. This feature offers significantly reduced cycle times for multi-operation parts and provides significant cost savings on larger production volume runs.

Other benefits include the following:

- Greater product design versatility

- The ability to handle an extensive material range

- Tighter tolerances with minimal chance of error

- The elimination of secondary machine processes

- Maximum production efficiency at high volumes

Swiss Screw Machine Capabilities and Project Examples

DW Products’ machining equipment features over a dozen turnkey Swiss CNC screw machines to meet your manufacturing needs. Our lineup includes two Hanwha swiss lathes, three Tsugami Swiss lathes and seven KSI Swiss lathes that offer superior machining by minimizing vibration and producing mirror-like finishes.

Examples of the types of products we produce with our CNC Swiss screw machine include:

- Shafts, Collars, Spacers and Pivot Bushings used in Automotive E-Brake Assemblies.

- Filter Adapter Fittings, Couplings, Boss Plugs and Temperature Sensor Ports for used in Filtration Component Assemblies.

- Threaded Axles, Rivets, Clevis Pins and Striker Bolts used in Latch Assemblies for the Agriculture, Off-Road Equipment, Truck & Bus, and Automotive markets.

Trusting DW Products for Your CNC Swiss Screw Machine Parts

At DW Products, we offer various CNC machining services to meet your specific manufacturing needs, including Swiss screw machining, multi-spindle screw machining, cnc milling, and more. Our engineers and manufacturing team leverage years of experience to design and produce the industry’s highest-quality, most durable and most cost-effective precision components, and other value-added capabilities.

Connect with us online to learn more about our CNC screw machine capabilities, or call 866-366-8455 to request a quote today.

GET A PROJECT QUOTE

WHAT DW PRODUCTS CUSTOMERS CAN EXPECT

-

EXCELLENCE

-

INNOVATION

-

ACCOUNTABILITY

-

RESPECT

-

INTEGRITY

-

SERVICE

-

QUALITY

-

DELIVERY

-

VALUE

-

CONTINUOUS IMPROVEMENT

WHAT DW CUSTOMERS CAN EXPECT

-

EXCELLENCE

-

INNOVATION

-

ACCOUNTABILITY

-

RESPECT

-

INTEGRITY

-

SERVICE

-

QUALITY

-

DELIVERY

-

VALUE

-

CONTINUOUS IMPROVEMENT